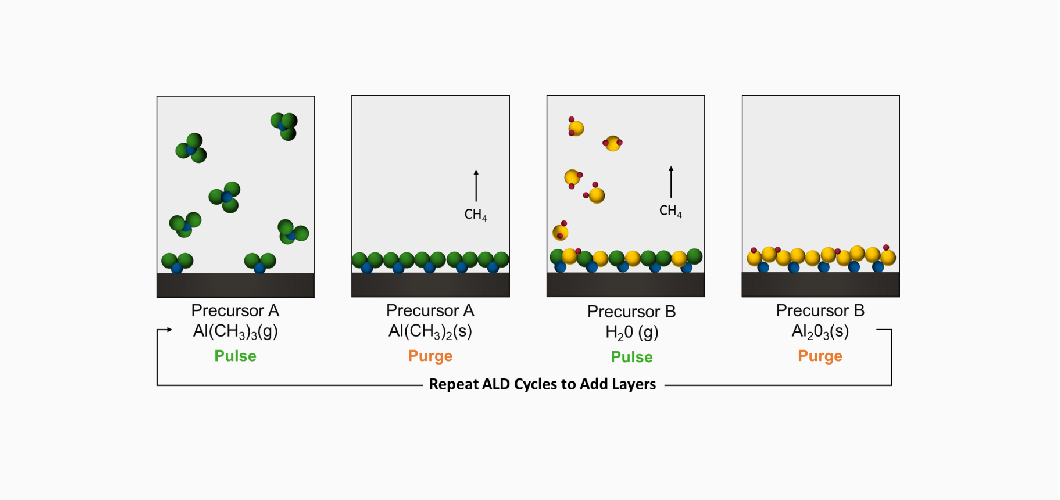

ALD refers to atomic layer deposition technology, PALD refers to Particle Atomic Layer Deposition,which belongs to the branch of atomic layer deposition technology. PALD is a proprietary technology for ALD coating on powder-based materials.

After years of development, Forge Nano has formed a variety of laboratory solutions including: fluidized bed, rotating bed, vibrating bed and so on. And the innovative use of space ALD technology makes it pioneered to achieve mass production of coating .

We are in the midst of a once-in-a-generation transformation. From fossil fuels to decarbonized, clean and sustainable energy. From internal combustion engines to electrified mobility.

To power this transformation, we need better batteries.

Batteries that look and act like today’s lithium-ion batteries but are built better. Batteries that deliver the functionality and value that automakers and consumers demand and deserve.

Atomic Armor improves the capacity and durability of lithium-ion batteries, making them charge faster and last longer – with better safety at a lower cost.

Atomic Armor delivers ultra-thin conformal coatings on semiconductor wafers and components, providing precise thickness control and robust film properties – superior to any other coating technology.

Atomic Armor – enabled by Forge Nano’s equipment and services – is more efficient and more cost effective than ever before.

Semiconductor fabricators can create hermetic, pin-hole free, low-stress thin films that offer excellent uniformity and precision for a range of applications, from 75-200mm wafers to fully assembled semiconductor packages ready for hermetic packaging.

Atomic Armor protects underlying material with an impenetrable, ultra-thin coating

3D printing is growing at an exponential rate, however, the technology still has significant limitations. Atomic Armor enhances the process to deliver higher-quality products.

3D printing is advancing the medical, dental, automotive, aerospace and defense industries.

Bespoke components with intricate designs and unique material properties can be made with ease for a wide variety of applications by 3D printing. Yet the technology suffers from significant issues that diminish product quality.

Applying Atomic Armor to metal 3D printing improves flowability, moisture/oxidation resistance, sintering interfaces and reduces inclusions.

Atomic Armor protects against unwanted reactions including oxidation during binder burnout

Atomic Armor stabilizes materials, adjusts flowability and allows for a more consistent material and end part

Using Atomic Armor, we can build a catalyst that is more stable, robust and selective to reduce the energy consumption during chemical manufacturing.

Catalysts play a profoundly vital role in major industrial sectors of the world’s economy, such as petroleum (oil and gas), chemicals production (e.g., polymers/plastics), and even the food industry. Using kinetic and thermodynamic measurements to calculate real world process variability, we can determine the impact of Atomic Armor on selectivity, fouling resistance, and regeneration. This means cheaper, more efficient production of consumer goods – and reduced greenhouse gas emissions.

Atomic Armor improves the thermostability, compactability, flowability and particle dispersion of the powder materials used in pharmaceutical ingredients and medical devices.

The pharmaceutical industry processes a wide variety of powder materials, from active pharmaceutical ingredients (APIs) to filler materials for use in divided powders. Powders are processed into capsules, tablets, pellets, inhaler doses or ophthalmic treatments such as eye drops. Atomic Armor enhances powder processability to reduce manufacturing time and cost.

Atomic Armor extends product shelf life by reducing the crystallization of powders

Atomic Armor improves thermostability, triples flowability and enables time-release control of single-administration medicines

Atomic Armor enables drop-in ready manufacturing and ease of distribution of medicines to reduce costs

If you want to know more about the product information, book a sample or consult the after-sales service, you are welcome to call our hotline 400 857 8882 or leave us a message online, we receive your message will be the first time to reply to you.