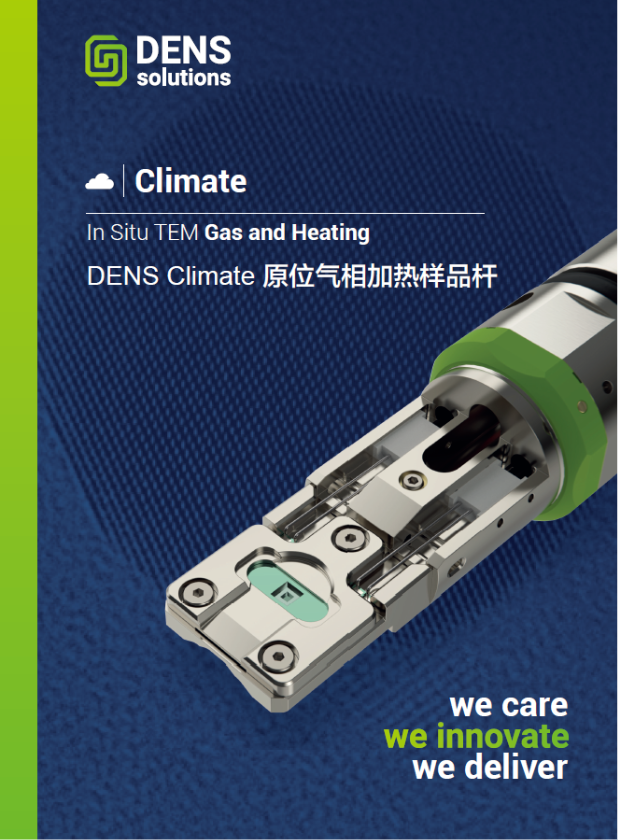

Climate's in-situ solutions offer state-of-the-art control of the gas environment and, using mass spectrometry, allow for excellent determination of the material's constitutive relationship

Dynamic mixing valves give the bars the ability to change gas composition and flow rate at any time, and the lmpulse software allows for the widest range of independent control of gas composition, pressure, and flow rate. four-probe heating provides the most accurate temperature control.

Temperature stability of 0.005°C is maintained even during gas flow.

Modular design for stability and reliability

Ultra Vacuum Performance

|

Mechanical Stability

|

Exchangeable Tubing & Tip

|

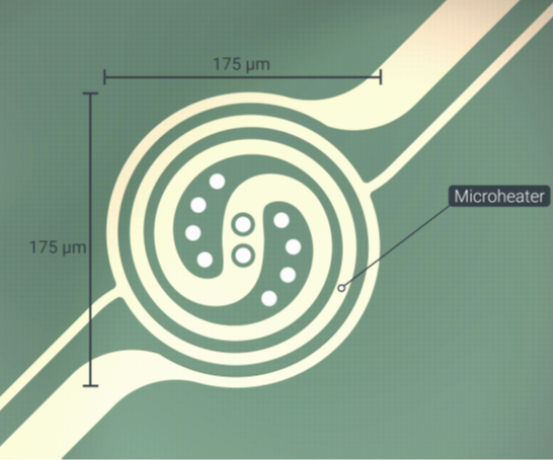

The in situ TEM Sample Holder provides the platform for connecting the Gas Supply System to the sealed Nano-Reactor inside the vacuum of the TEM. The modular design allows for each vacuum component to be either cleaned or replaced which ensures each new experiment is free from cross-contamination. The highest precision fabrication techniques were used to machine the in situ TEM Sample Holder to perfectly fit the microscopes goniometer.

| 产品规格参数 | Climate Air | Climate GVB | Climate G+ |

| Heating control mode | 4-point probe resistive feedback | 4-point probe resistive feedback | 4-point probe resistive feedback |

| Heating range | RT - 1,000 °C | RT - 1,000 °C | RT - 1,000 °C |

| Heating & cooling rate | Up to 150 °C/sec | Up to 150 °C/sec | Up to 150 °C/sec |

| Temperature stability | ≤ ± 0.01 °C | ≤ ± 0.01 °C | ≤ ± 0.01 °C |

| Pressure range | Ambient | 0 - 2,000 mbar | 0 - 2,000 mbar |

| Resolution* | ≤ 100 pm | ≤ 100 pm | ≤ 100 pm |

| Drift rate* | ≤ 0.5 nm/min | ≤ 0.5 nm/min | ≤ 0.5 nm/min |

| Modular holder design | Yes | Yes | Yes |

| On-chip ffow channel | Yes | Yes | Yes |

| Mass Spectrometer | 0 - 200 AMU | 0 - 200 AMU | 0 - 200 AMU |

| Gas mixing method | N/A | Discrete | Continuous |

| Mixing ffammable mixtures | N/A | No | Yes |

| Gas switching | N/A | 10 min | ≤ 15 sec |

| Gas input lines | N/A | 3 | 3 |

| Gas ffow range (normalised) | Static | 0, 0.01-1 ml/min | 0, 0.01-1 ml/min |

| Vapor compatibility | N/A | Yes | Yes |

| Micro-calorimetry | Yes | Yes | Yes |

| EDS compatibility** | Yes | Yes | Yes |

| EELS compatibility | Yes | Yes | Yes |

-

Green energy materials

Green energy materials -

Corrosion of metals & alloys

Corrosion of metals & alloys -

Materials synthesis and growth

Materials synthesis and growth -

Heterogeneous catalysis

Heterogeneous catalysis

-

“The DENSsolutions Climate System allows us to reveal the so-far unseen: Looking at not only how the gas-phase is changed in the presence of a catalyst, but also studying how the interaction between gas-phase and catalyst leads to the emergence of catalytic function. Direct real-space observation is essential for our understanding of working catalysts and the development of new processes that are urgently needed in view of climate change and limited natural resources.”

Prof. Dr. Wei Liu Professor | Dalian Institute of Chemical Physics, CAS -

The DENSsolutions Climate System allows us to reveal the so-far unseen: Looking at not only how the gas-phase is changed in the presence of a catalyst, but also studying how the interaction between gas-phase and catalyst leads to the emergence of catalytic function. Direct real-space observation is essential for our understanding of working catalysts and the development of new processes that are urgently needed in view of climate change and limited natural resources.”

Prof. Dr. Marc-Georg Willinger Professor | Technical University of Munich -

The DENSsolutions Climate system allowed us to directly evaluate the reducibility of Fischer-Tropsch catalysts under industrially relevant temperatures. Such observations provide a unique insight into the evolution of catalysts under activation conditions.

Dr. Ofentse Makgae Post-doctoral Research Fellow | Lund University

If you want to know more about our products, please contact us.