Overview

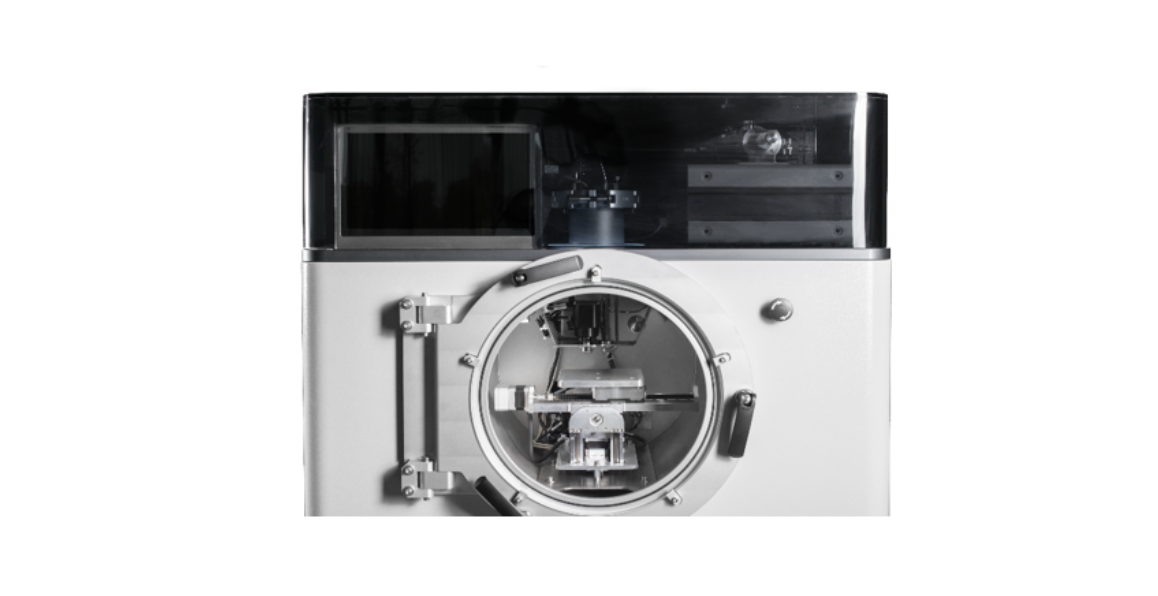

Easily and controllably print nanostructured layers, the VSP-P1 NanoPrinter is the ultimate prototyping and R&D platform for materials development and small-scale production testing. Based on stamping deposition of spark ablative materials, the system employs additive manufacturing to simplify the production of nanoporous films and layers with high surface-to-volume ratios.

Parameters

-

Modular combination 01

1-2 sets of VSP-G1 nanoparticle generator can be built-in as a material source;

It can be used with VSP-S1 particle size screening deposition module for printing fixed particle size.

-

True dry aerosol deposition 02

The particles are produced entirely from VSP-G1 without any ink components added;

The particles are produced by physical methods and do not contain any chemical additives.

-

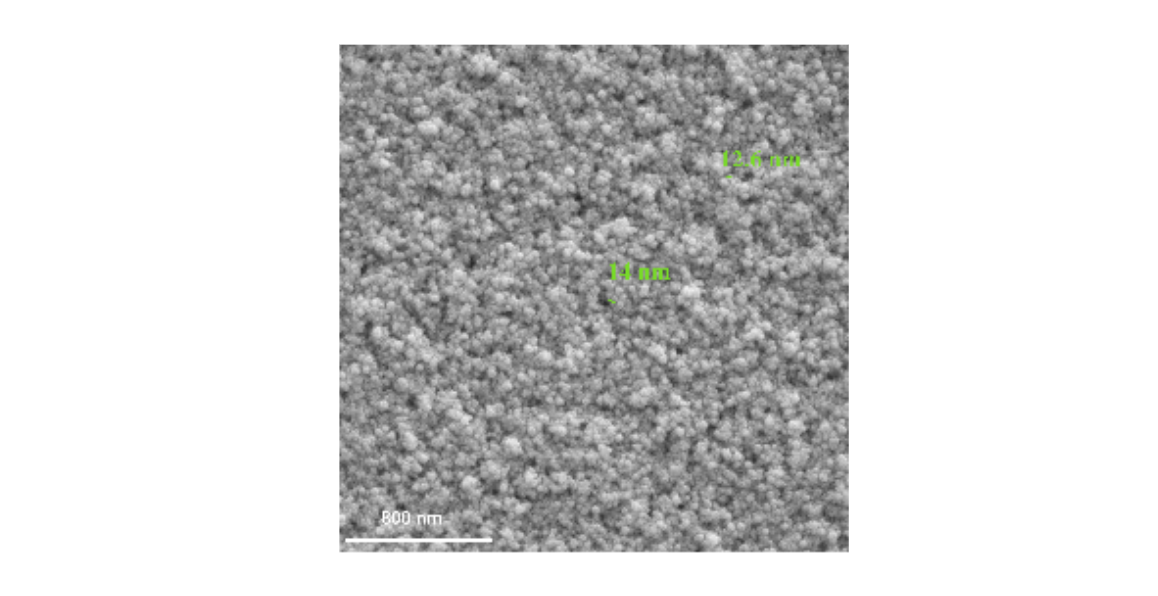

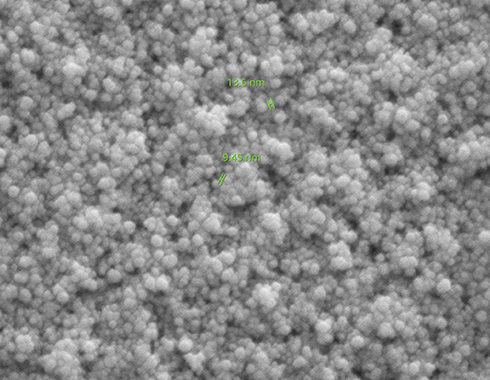

Ultrafine nanoparticle print deposition 03

Rapid deposition of alloys or mixtures of heterogeneous nanoparticles;

Aerosol typical particles have an initial particle size < 20 nm

- 01 Control nanodeposited layer thickness

- 02 Patterned printing

- 03 Nano porous coating deposition

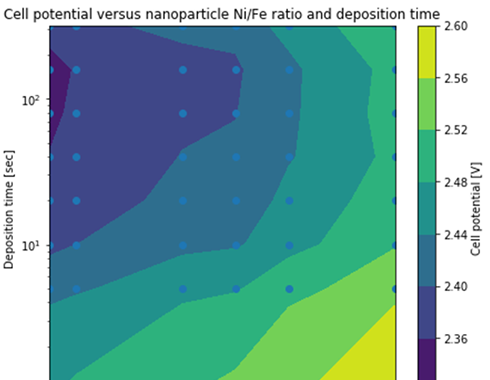

The parameters that affect the layer thickness are:

• The distance from the nozzle to the substrate • Ablation power • Printing speed

After the nanoparticles are generated by VSP-G1 spark ablation, the aerosol stream generated using coarse vacuum acceleration passes through the nozzle. Therefore, the driving force of impact printing onto the substrate is the pressure gradient between the VSP-G1 system and the deposition chamber.With XYZ stage control, microscope camera modules, and an intuitive user interface, specific patterns can be printed. You can run a script through the user interface to determine the desired print mode. Series production with different or modified scripts, complex patterns and multiple samples.

.png)

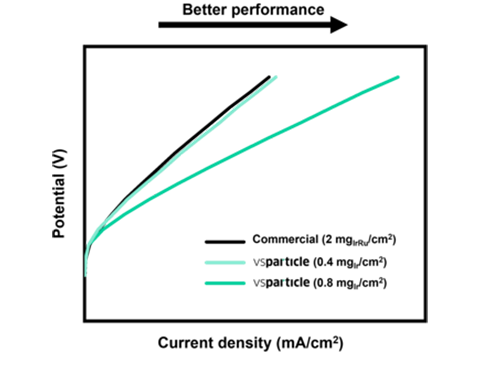

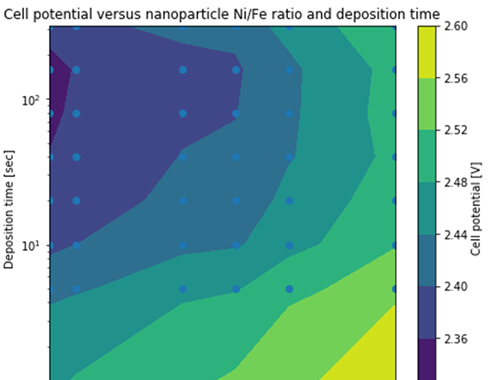

Unlike traditional thin film deposition technology, VSP-P1's aerosol direct writing technology can deposit nano-coatings in selected areas and use fine nozzle movement to achieve thickness control, which is well suited for non-semiconductor nanofilm applications.

-

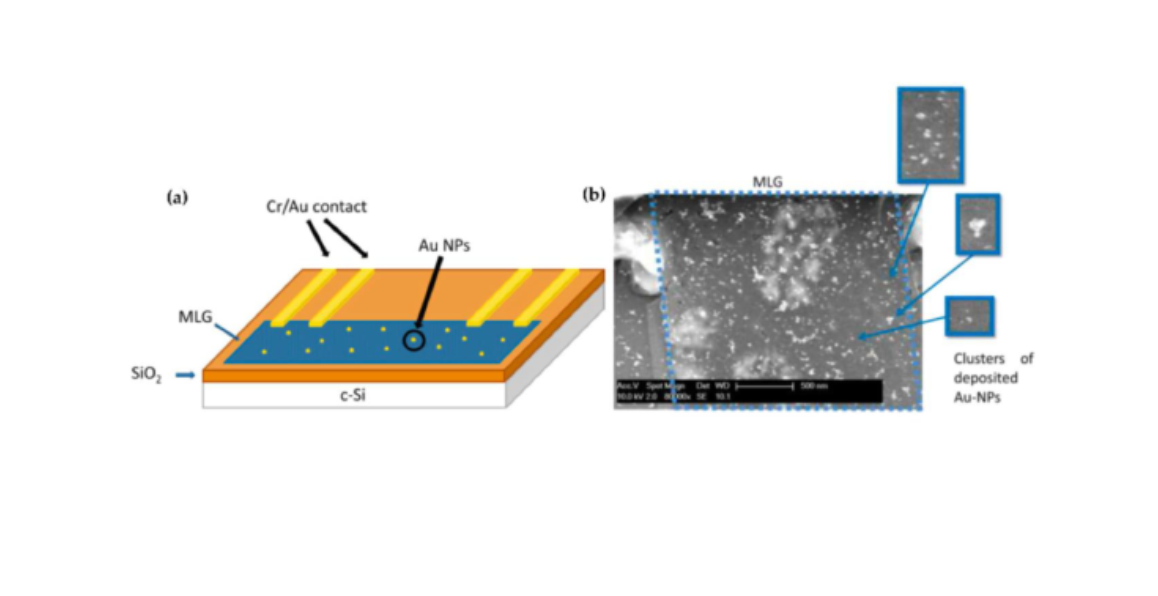

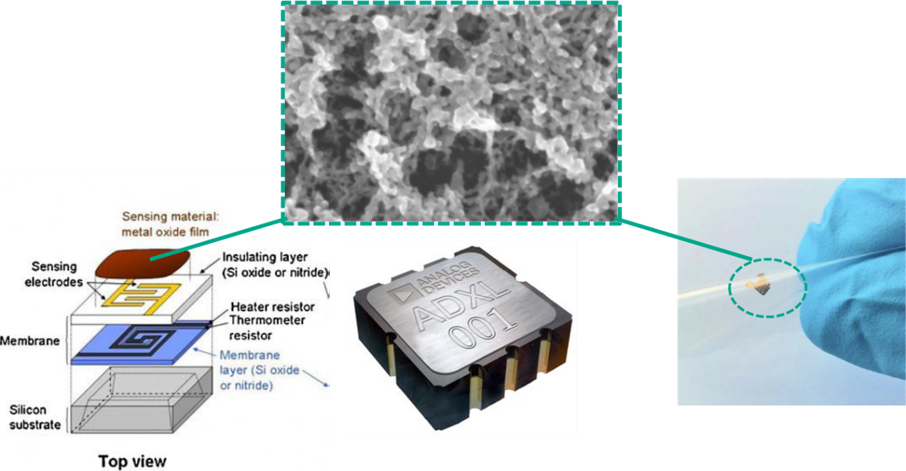

“With the use of the VSP-P1 NanoPrinter I have been able to implement all my ideas when it comes to decorating biosensors with nanoparticles. I really like that I can choose between a lot of different parameters and get exactly the size and quantity of nanoparticles that I desire but also combine different materials.”

Merlin Palmar Master's in biomedical engineering at Delft University of Technology, Bioelectronics department -

“The versatility and material flexibility of the nanomaterials printer allows us to print a wide range of nanomaterials on finished microelectronics devices. We are now able to decorate gas sensors and deposit on thin membranes and other fragile substrates without putting too much effort in finding a good recipe. Because it’s so simple to test something new, we can think of new experiments often and perform them the next day!”

PhD Candidate Joost van Ginkel Department of Microelectronics TUDelft

If you want to know more product information, please fill in the following information to download the product manual.

如果您想要了解更多产品信息,请填写以下信息下载产品手册, 我们收到您的信息后将第一时间回复您。

.png)

.png)

.png)