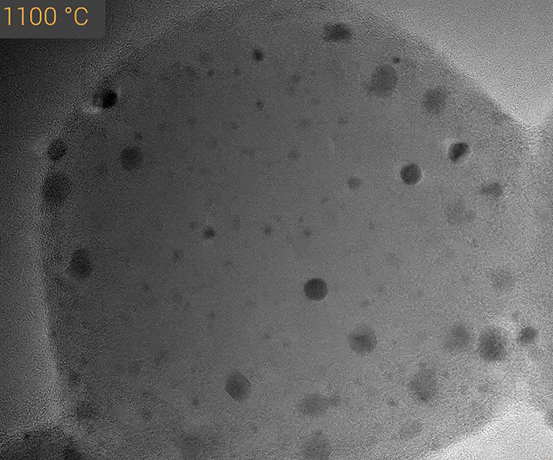

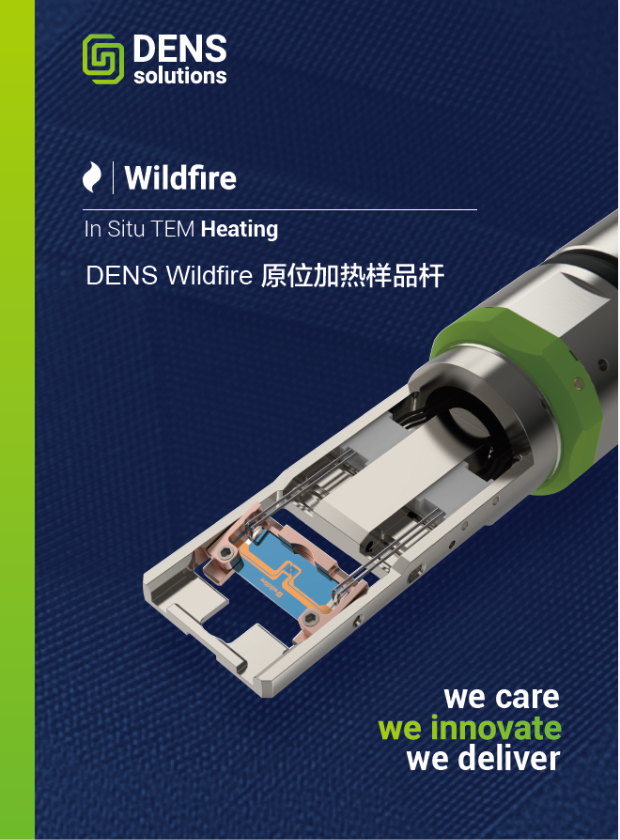

Investigating materials while changing temperature expands the application space of conventional TEM and enhances its already powerful imaging capabilities.

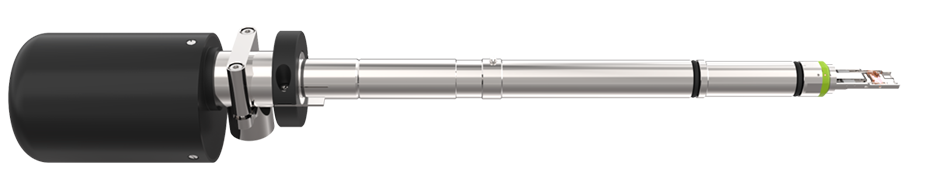

The Wildfire system allows for researchers to heat from room temperature to 1,300 °C with the ultimate temperature control and ultimate sample stability in all directions.

The stability of the Wildfire system ensures that the full resolution and analytical performance of every TEM can be maintained while observing sample dynamics at elevated temperature.

Modular design for stability and reliability

Compatible with mini-pole gap

|

Double tilt

|

Mechanical Stability

|

EDS Optimized

|

The sample holder brings the Wildfire Nano-chip into the TEM. samples are made of material with optimal mechanical stability and are designed for direct integration into ThermoFisher or JEOL microscopes.

| JEOL | Thermo Fisher Scientific | |

| Heating control | Closed 4-point probe feedback loop | Closed 4-point probe feedback loop |

| Temperature range | RT - 1,300 °C | RT - 1,300 °C |

| Polepiece compatibility | All | Bio-TWIN, C-TWIN, TWIN, X-TWIN, S-TWIN |

| Alpha tilt range | URP, FHP ≥ ± 15 deg HRP, WGP ≥ ± 20 deg | ≥ ± 25 deg |

| Beta tilt range | URP, FHP ≥ ± 15 deg HRP, WGP ≥ ± 25 deg | ≥ ± 25 deg |

| Attainable resolution* | ≤ 60 pm | ≤ 60 pm |

| Drift rate* | ≤ 0.5 nm/min | ≤ 0.5 nm/min |

| Temperature accuracy | ≥ 95 % | ≥ 95 % |

| Temperature Homogeneity | ≥ 99.5 % | ≥ 99.5 % |

| Viewable area | 850 µm2 | 850 µm2 |

-

Low Dimensional Materials

Low Dimensional Materials -

Nanotechnology

Nanotechnology -

Materials Engineering

Materials Engineering -

Materials Energy Applications

Materials Energy Applications -

Soft Matter Systems

Soft Matter Systems

-

“In-situ TEM provides a new dimension in dynamic structural studies of a range of technologically important materials. The Department of Materials at Oxford will use the DENSsolutions sample heating holder in a number of projects related to catalysis and low dimensional carbon materials. We have chosen this solution for its unrivaled stability and control.”

Angus Kirkland Professor of Materials University of Oxford, United Kingdom -

“The DENSsolutions holder impressed me with high resolution imaging and extreme stability at high temperatures. It is exciting that the picture taken with the DENSsolutions holder shows superior performance compared to other holders. As long as we have got the DENSsolutions holder, we have got the in-situ world spinning in our hand.”

Professor Xiaoyan Zhong Tsinghua University Beijing, China -

“In-situ Transmission Electron Microscopy is one of the most exciting avenues for future breakthroughs in the characterization of dynamic processes in nano scale materials and devices. The DENSsolutions sample heating systems have performed impressively in experiments carried out in the Ernst Ruska-Centre.”

Professor Rafal Dunin-Borkowski Director, Ernst Ruska-Centre (ER-C) Forschungezentrum Jülich, Germany

If you want to know more about our products, please contact us.